Gary Wilkinson, Regional Director, Wessex

Bay Window repair

I’m the Regional Director for the Wessex franchise, and I want to share recent works that highlights just how effective modern metselwerkwapening can be when tackling serious structural issues like verzakkingsproblemen.

We were called to a property in Wiltshire with a classic problem: a two-storey bay window suffering from significant verzakkingsproblemen that had led to concerning scheuren in de muur and general masonry movement.

The Problem: A Detailed Look at the Damage

When we surveyed the home, here’s what we found:

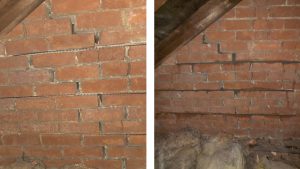

- Rear Cracking: The most worrying sign was a severe crack above the rear bedroom window. Inspection from the roof space confirmed significant movement, with a maximum of 20mm horizontally and 12mm vertically at the top of the crack. This indicates the wall was under serious stress.

- Historic Movement: Externally, minor cracking was visible above the window, extending from the lintel. Crucially, we noted widened and uneven perp-joints that had been previously repointed. This told us the movement was historic and, interestingly, affected the adjacent property too—a strong indicator of a widespread ground issue.

- Bay Window Distress: The front bay window itself showed cracking in the left pillar and through the window sill. The pillar was bowing outwards, possibly due to inadequate lateral restraint and water from a nearby downpipe, which could be affecting the subsoil.

This property needed a comprehensive solution to stop the verzakkingsproblemen and repair the resultant scheuren in de muur. We addressed it in three key stages.

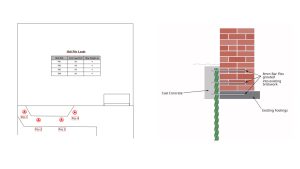

Step 1: Precision Crack Stitching and Beaming with Bar Flex

To stabilise the existing masonry and close the cracks, we employed our high-performance Bar Flex system.

- What we did: We installed 6mm Bar Flex to perform scheurnaden on the damaged pillar and for beaming underneath the first-floor bay window.

- Why Bar Flex? Bar Flex is an ideal material for these works because it dramatically improves masonry structural behaviour while keeping the original appearance intact. It develops greater strength under tension than regular steel and provides a smoother transition between its elastic and yielding stages.

- The Process: We cut slots into the horizontal mortar joints, cleaned them thoroughly, and inserted a bead of our high-strength Bond Flex grout. The pre-cut Bar Flex was pushed into the grout, and then another bead of Bond Flex was applied over the bar, finishing by ironing the mortar back into the joint—a seamless, strong repair.

Step 2: Ending Subsidence with Heli Piles

The next critical step was to address the root cause: the ground movement. This required deep foundation underpinning.

- What we did: We installed 100mm Helipalen in four positions around the bay window. Each position had four metres installed.

- The Testing: Once installed, the piles were tested to reach a strength of 60 kN (kilonewtons). Every position comfortably tested over 70 kN, confirming they are anchored deep into stable ground.

- The Finish: To complete the foundation bond, we bent 8mm Bar Flex around the Helipalen in three positions and grouted it into the brickwork and down to the foundation. We then poured concrete to create a solid cap, ensuring the foundation bond is complete and that there will be no continuing movement on the bay window.

Step 3: Interior Consolidation

Finally, the full structural integrity was restored by addressing the internal damage caused by the overall masonry movement.

- What we did: We used 6mm Bar Flex to perform scheurnaden on the heavy step cracking visible on the interior of the gable end. This was essential to consolidate the inner leaf, which had been affected by the movement of the entire two-storey structure.

The result? Another happy customer in Wessex with a property that has been saved from further damage! Our engineered solutions stop verzakkingsproblemen at the source and provide a discreet, long-lasting repair for all forms of scheuren in de muur.

Do you have scheuren in de muur of masonry movement that you suspect is related to verzakkingsproblemen of bay window repair issues? We can survey your property and provide a tailored reinforcement plan. Neem contact met ons op today!

Engels

Engels

Comments are closed